RFFMIDT: A Dashboard System for Maritime Crane Condition Monitoring (2021-2022)

Project Partners

NTNU, Seaonics AS, Offshore Simulator Centre AS

Project Description

Cranes are important deck equipment in many offshore and subsea applications for lifting, transferring, and handling objects and personnel. Unlike the operation of land-based cranes with fixed working platforms, maritime crane operation is always a challenging task which involves many problems such as load sway, positioning accuracy, suppression, collision avoidance, and manipulation security. More importantly, external perturbations such as wind, wave and current play an important role in work efficiency and safety due to the tight coupling between the ship and the on-board crane. How to improve the safety level of maritime crane operation therefore becomes increasingly significant and necessary for maritime industry.

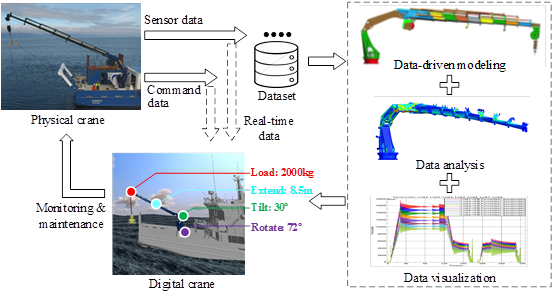

To date, the industry internet of things (IoT) is of high interest for crane companies and equipment suppliers. Digitalization has become a key aspect of making the maritime industries more innovative, efficient and fit for future operations. In this project, we take advantages of expert knowledge from Seaonics AS – a company striving for better performance and energy-efficient solutions of cranes, together with Offshore Simulation Centre (OSC) AS – a professional offshore operation simulation company, to develop a dashboard system from crane data transmission, modelling, analysis to visualization. The dashboard system will not only generates valid digitalized models of maritime cranes but also provides an efficient way to monitor crane operation and predict necessary maintenance.

Objectives

The following shows the project concept. This project lasts 12 months, we have the following secondary goals:

- Create both mathematical model and 3D model of the testbed crane, and utilize historical sensor data to identify system parameters of the crane

- Build tools to reproduce crane operations via real-time sensor data, assess operational safety and estimate maintenance time based on historical sensor data

- Make a case of heavy-lifting operation and verify the dashboard system in OSC platform